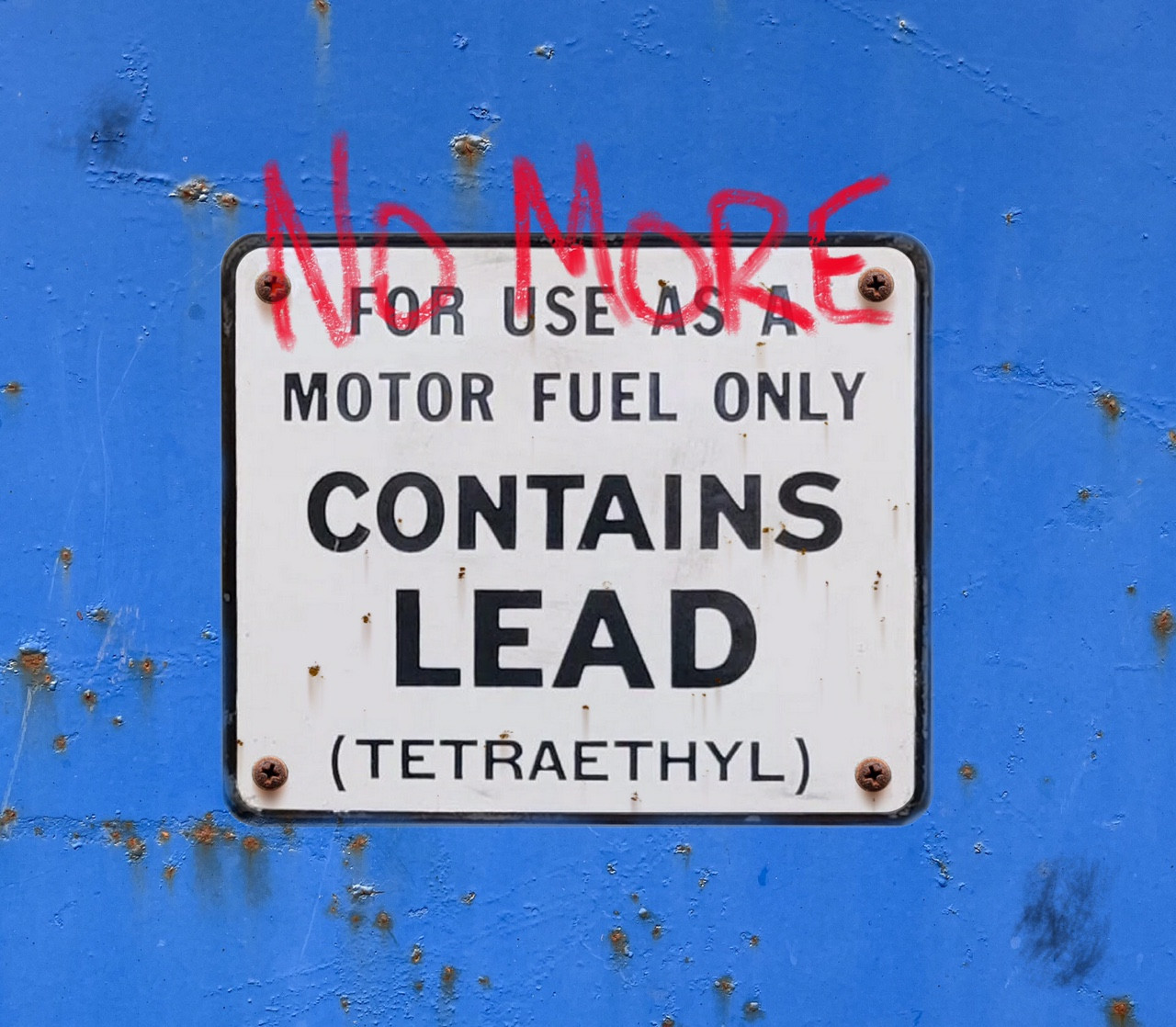

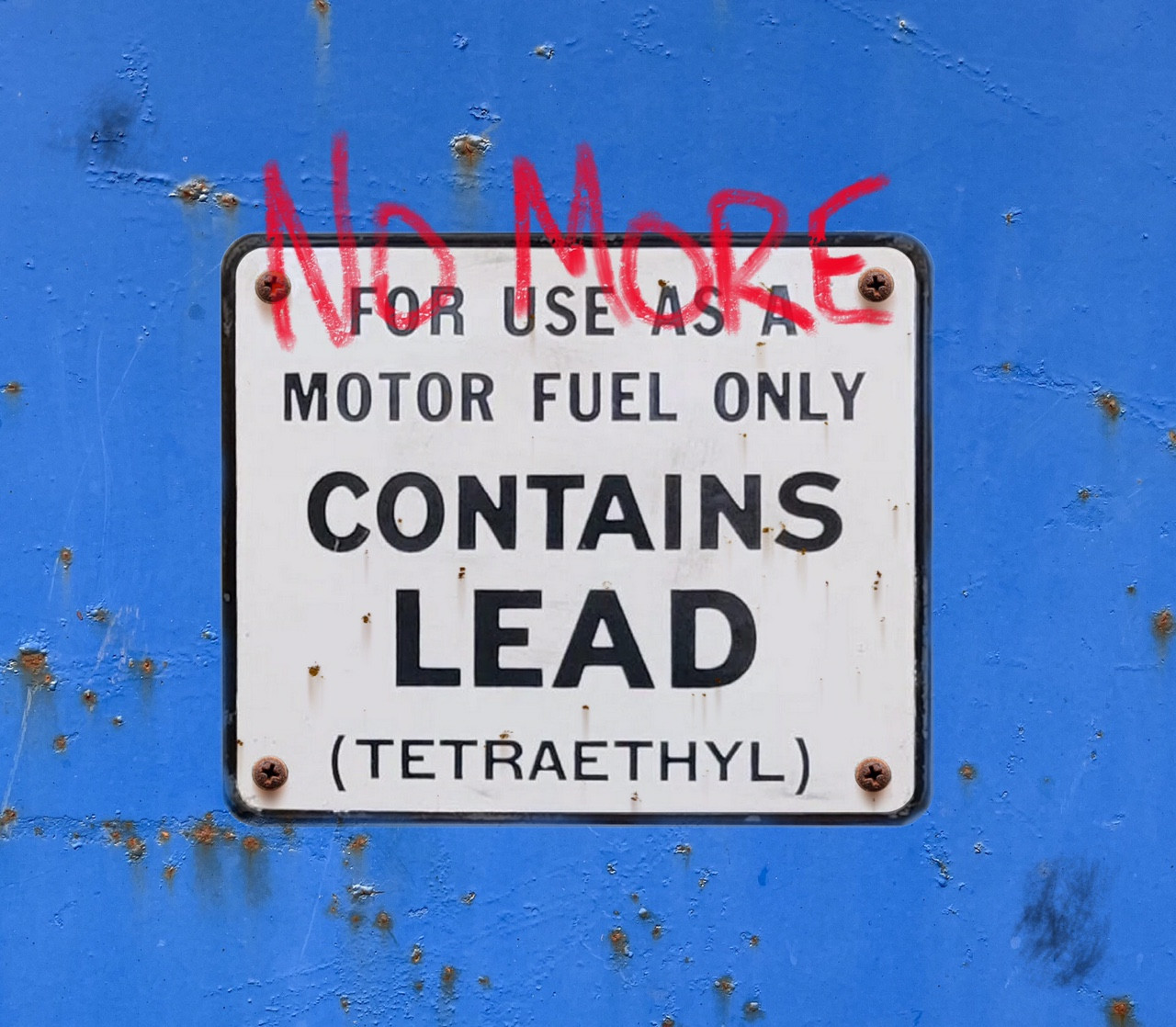

Sign that used to appear on leaded gasoline pumps.

American Chemical Society | Industry | Industry Matters Newsletter | Getting the Lead Out

Get The Lead Out

Industry Matters Newsletter 18 November 2021

The end of August 2021 was the end of a sad century in

the history of chemistry. Headlines

proclaimed the world finally

stopped using leaded gasoline.

The

UN announced Algeria used the last of its automotive leaded gasoline

stockpile on August 30.

Looking through today’s eyes, knowing the damage caused

by leaded fuel, it seems impossible to consider putting lead into gasoline.

Indeed, much of the

reporting on leaded

gasoline paints the inventor, Thomas Midgley, as a Shakespearean

villain. Midgley is declared by

some to be the person responsible for more

environmental damage than anyone else in human history, the

individual chemist responsible for impacting the most lives.

The history is far more complex.

My first encounters with the Midgley story conjured a

picture of a rogue chemist operating on the fringes of the chemical enterprise.

I was wrong. Midgley was

awarded both the Perkin and Priestley medals, two of the highest honors in

chemistry. He was elected to the

National Academy. He was

president of the ACS and a long-time board member.

He was mainstream. He was

lionized for his accomplishments, especially leaded gasoline.

Sign that used to appear on leaded gasoline pumps.

Attempts to get more horsepower out of internal

combustion engines prompted a move to higher compression.

Pushing to higher compression ratios dramatically increased engine

performance, but uneven combustion caused engine knocking.

In 1921, Midgley found tetraethyl lead (TEL) proved effective at very low

concentrations to stop knocking.

Added at 0.4 g/L, it doubles the horsepower of an engine. To reach the same

horsepower, an engine could be half the size, burning half the fuel. TEL

effectively doubled the constrained gasoline supply of the day.

It was nothing short of revolutionary, except for the toxic part.

Electrification stands tall as one of the major ways the

world will decarbonize. Many of the

materials we’ll need for the photovoltaics, the wind turbines, the batteries,

and the wires are metals. The

extraction, smelting and purification will release lead from the ores. There

aren’t zero lead options. We face

Midgley’s dilemma, trading one environmental burden against another.

Determining an acceptable level of lead emissions needed

to reduce greenhouse gas emissions is, admittedly, a fool’s errand, fraught with

peril and reliant upon many potentially flawed assumptions.

I’ll use a false equivalency to set the limit, just for the sake of

argument. I’ll take the lead pollution

created in electric vehicle production, assume EV CO2 emissions are

zero, and estimate how much lead is released for those reductions.

Many materials

associated

with lead are needed for EVs, but I’ll consider only copper.

Copper

production today releases nearly

13 thousand tons of lead.

EVs will make up

7.5% of the

operating fleet in 2030, increasing copper

demand by 2.8 million tons.

About 1800 tons of lead emissions will be associated with increased copper

production needed just for EVs. I’ll

assume 7.5% reduction in CO2.

That reduction will release about 8 grams of lead per ton of avoided CO2

just for the copper associated with EVs.

Applying this factor to the current global gasoline

market of over

900 million tons, accounting for

3 billion tons of CO2 emissions, gives 13.5 ppm as the lead level

in gasoline to halve the CO2 as proposed in the thought experiment.

CO2 emissions are halved while emitting lead at the level EVs

do per avoided CO2. That

is about one fortieth the level in leaded gasoline and much more than I

expected. Peak leaded gas use in

the U.S. occurred in 1970, placing 250 thousand tons of lead into the

environment. For all the rhetoric

about no safe lead levels, our best environmentally friendly technologies have

an environmental lead footprint too close for comfort to leaded gasoline, a

technology pariah.

Midgely both knew and experienced the hazards of lead.

Today, he is pilloried by many for concluding the benefits were worth the

risk. Used in products or as a

byproduct associated with other manufacturing, lead emissions continue.

We continue to face Midgley’s dilemma.

Just as he did, we trade benefits against lead’s risks.

Editor’s Note: If you enjoyed this piece by Mark Jones,

you may be interested in reading an

expanded

version of this article, which recently appeared in R&D World.